Sailing dead downwind across the Atlantic from the Cape Verdes to St. Lucia in light air was the true test of the “green” energy systems on Archer, our Outremer 51 catamaran. ( Published Fall 2015)

It was a highly successful test—With our solar panel array and hydrogenerator, we ran the engine to create power under five percent of the 12 and a half day (300 hour) passage.

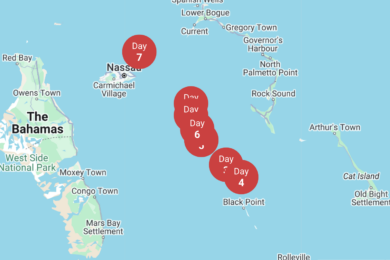

Our engine usage during our transatlantic passage was very limited; see Figure 1.

When we switched to a catamaran a year ago after 35 years on a monohull, one of our goals was to outfit Archer with simpler systems. In the 12 years we owned Altair, our Saga 48, we allowed new technology to lure us to more complex systems than we really needed. More complexity meant more maintenance, more failures, more frustration, and more spare parts on board.

Our energy system on Archer is one that we tried to design as simply as we could and still reach our goals to sail on passages with minimal diesel consumption and “park” at anchor for at least three days without running the engine to charge batteries. Archer is equipped with 560 watts of solar panels, mounted on the dinghy davits and a Watt & Sea hydrogenerator, mounted on a bracket on the aft end of the port hull. For simplicity and weight considerations we chose not to have a generator and as a personal preference we decided not to add a wind generator.

On the energy-consumption side, while on passage we routinely run the following 12V systems: the autopilot, instruments, chartplotter, radar if squalls are in the area, computer for backup charts and communication using our sat phone, VHF and SSB, fridge and separate freezer and navigation lights. We generally make water once every three days. A 120V inverter allows us to run small appliances (coffee maker, yes, the Nespresso has become a necessity, and a toothbrush charger). Again, for simplicity and weight considerations on Archer we chose not have a washer/dryer, dishwasher, microwave, or ice maker.

MAKING WATER

On the transatlantic passage, we only needed to run the engine to produce power when we wanted to make water. While, in actuality, the solar panels and Watt & Sea could replenish the amps drawn from the batteries, the watermaker manufacturer recommends running the engines to ensure full voltage. The watermaker on Archer draws approximately 40 amps to produce 26.4 gallons (100 liters) of water per hour. We want it to run at full efficiency. Our watermaker is about average in power consumption one and a half amp/hours per gallon of water made. |

MEASURING THE BATTERY CHARGE

The marine market is flush with gauges and monitors to judge the performance of energy systems. On Altair, we installed a sophisticated device that displayed minute-by-minute amp production from each power generator (wind, solar, hydro, alternator, and battery chargers) separately. It also measured the status of the battery charge in amp-hours and percent. After struggling with installation for several months, we found the device to be accurate and fascinating. It was tempting to sit at the navigation station and watch the input from all sources change with conditions and boat speed. But, we felt it was analogous to reading time with a chronometer that displays to a hundredth of a second when, as a cruiser, you really only need to know when it is time for happy hour, give or take an hour or so.

The bottom line in measuring energy system performance, in our view, is to know the cumulative effect on our batteries of operating the boat. So, on Archer, we installed a single-point metering system using a Victron BMV-600S, and focused on battery voltage rather than amp-hour calculations to understand the condition of the battery bank. We have chosen to monitor voltage instead of amp-hours because we felt there were opportunities for inaccuracies in amp-hour calculations, especially on long passages when charging rates vary greatly.

Our goal on passages is to keep the battery bank within 85 to 95 percent of its fully charged state. The solar panels and hydrogenerator allow us to operate within this range effectively. At anchor, we do not allow the batteries to drop below 65 percent of full charge and, when necessary, perhaps after three days, use the alternators to re-charge the batteries.

To determine the percent charged accurately, it is important to read the Victron meter when the power sources are not active. We take our daily readings at night (no sun) and when the hydrogenerator is out of the water. Whenever we are in a marina, we plug in to shore power and use our battery charger to charge the batteries to full capacity. We follow the battery manufacturer’s instructions for equalizing the batteries to remove sulfates from the plates to ensure maximum performance from the batteries long-term.

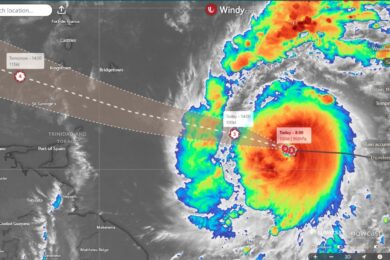

We use a chart from our battery manufacturer, similar to the one in figure 2, to understand the relationship between charging percentage and voltage. If our batteries are charged within our selected range, we are keeping up with power consumption pretty well. We find that monitoring the percent charged, rather than watching amp hours, is an effective and simple method for us to measure the total balance of our energy systems.

INSTALLATION NOTES

Our solar panels were factory-installed and we have made no modification to them in our first year with Archer. For those considering modifications to their solar array, flexible panels on the bimini top can increase total power production. In addition, adapting the mounting system for existing panels to be able to position them toward the sun may allow for longer peak performance from the panels.

In the manufacturing process, we modified the standard Watt & Sea hydrogenerator (Model 6—00W, 610 mm) mount to make the unit removable. By storing it in a locker integral to the port hull when not in use, we eliminate the opportunity for damage when docking stern-to and prevent theft. After the first year of use, we discovered that the manufacturer-supplied external “waterproof” electrical connector was prone to corrosion after we repeatedly mounted and un-mounted the unit. We re-wired the unit to eliminate the exposed connections.

We are careful to follow the manufacturer’s recommendation on prop size. We carry two sizes, 200 and 240 millimeters. If we expect to sail in light conditions, we use the larger prop. When we expect to sail consistently over eight knots, we use the smaller prop.

We are very pleased with the reliability and simplicity of the energy systems we have on Archer after a year and over 7,000 miles. As components need replacement and technology evolves, we will evaluate our options to make modifications—but always with an eye on our goal to keep the boat simple and easy to maintain.

Rick Palm has made a circumnavigation with his wife Julie and for the last decade they have worked with the Caribbean 1500 as advisors and inspectors.